About Retort

Retort Description

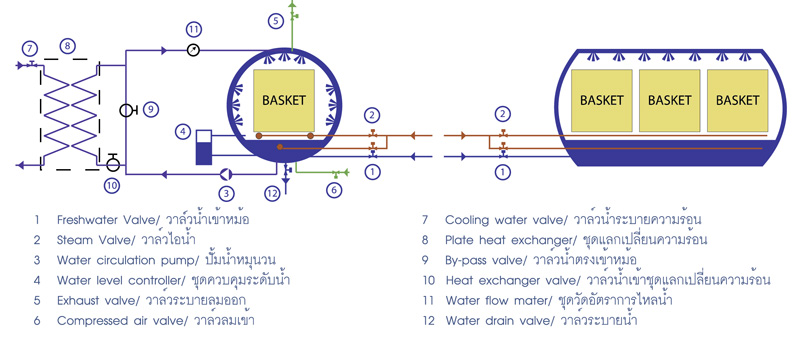

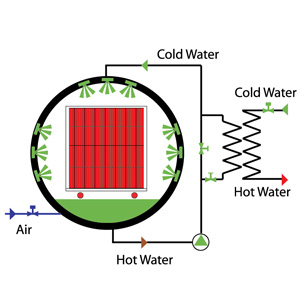

The KM Steam and Waterspray Overpressure Retort with Thermal Process Programmable Logic Controller (PLC) designed for thermalprocessing all kind of container such as Aluminum Retortable Pouches, Glass Jars, Plastic or Aluminum containers, etc. With directed steam injection, continuous waterspray from top and sides operation guarantee homogeneous heat distribution in the vessel during both sterilizing and cooling. Besides, temperature and overpressure are independently programmable, PID controlled and then recorded by circular chart recorder. Overpressure can be programmed at all time during the heating and cooling for reduced stress on the container seals. Programmes are stored in the memory of the PLC

Working Principle

|

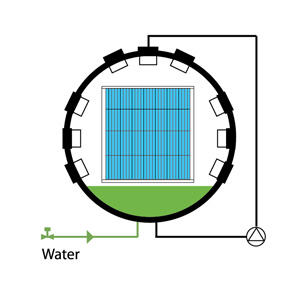

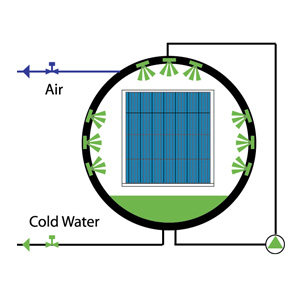

Water Filling After loaded the baskets and closed the doors to begin process, freshwater (appx. 100 liters per basket) is filled into retort up to certain level (held under baskets), which is always controlled by water level controller. This water also could be pre-heated up to required temperature to prevent temperature drop of products at start of process. |

|

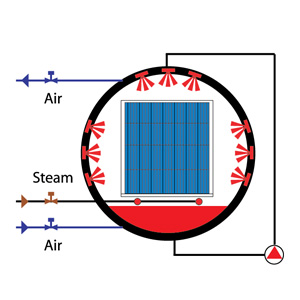

Heating Once water is filled up to required level, circulation water pump is started automatically, meanwhile steam valve and air valve would also open to heat up and counter pressure products package inside (without deformation). The water circulated through numbers of spray nozzles would create mixing of cold air and steam, resulting fast and perfect homogeneous temperature distribution in retort. |

|

Sterilizing Once sterilized temperature and pressure pre-programmed have been reached, PLC would control both parameters constantly until the rest of sterilized time by mean of modulating air valve, steam valve, exhaust valve and water drain valve, meanwhile water pump is kept running to guarantee homogeneous temperature distribution inside retort. |

|

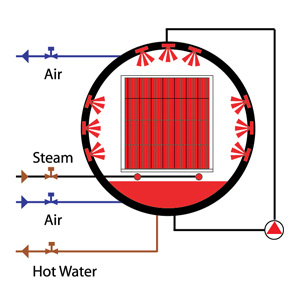

Cooling Once sterilization is finished, cooling phase is on automatically. At this moment, steam valve is closed, then water valve is opened to have cooling water from cooling tower flow through Plate Heat Exchanger, then take heat from sterilized water back to cooling tower. In this moment, pressure inside is maintained constantly awhile to hold product package not to deform or break in early cooling period. During cooling phase, multiple cooling steps is programmable to reach fine cooling in early stage and fast cooling in later stages. Certainly water pump is kept on running throughout process, besides, drain valve is opened if water level is excessive. |

|

End of cycle Once temperature is cold and reaches to programmed value, water circulation pump is off, meanwhile exhaust valve, drain valve is fully opened to release pressure and water inside. Once pressure is fully released, safety door locking system is off allow door opening and unloading of baskets. |

Designed By Megaweb.co.th